INJECTION MOLDING

PLASTIC INJECTION MOLDING

For your plastic injection molding needs, EPower Corp is considered one of the most dependable contract manufacturers in China. We serve American companies looking for high-quality, short lead times and competitive pricing.

In Simple Terms, What is Plastic Injection Molding?

Plastic injection molding is the process of melting plastic pellets into a molten fluid that is injected into a mold and cooled until the product is to the desired shape.

EPower Corp currently operates 15 plastic injection molding machines with the largest one being 550 tons (tool dimensions of approximately 36 in x 36 in). Our strong history of using high-quality tools combined with our strict management system gives us a quality and price advantage.

Over the past 12 months, EPower's injection molding machine efficiency has increased by 13% making our process even more competitive.

EPower Corp

EPOWER ADVANTAGES

-

Responsiveness - The whole EPower operation has been optimized for faster response times on quotes and questions

-

Greater Productivity and Less Downtime - Reduce machine setup time makes your quote more competitive, including shorter lead times

-

Reduced Investment - The price of our tooling and fixtures are less expensive making you quote more competitive

-

Improved flexibility - We have the capability to make samples and high volume production runs and everything in between

-

Consistent Quality - We continually strive to improve product quality and consistency

-

DFM (Design for Manufacturing) - EPower offers DFM services to many customers to make sure their design is optimized for manufacturing efficiency and quality

SECONDARY OPERATIONS

Secondary Operations & Finishing:

We offer secondary to help complete your product. These can include one or more of these:

-

Ultrasonic Welding

-

Pad Printing

-

Laser Etching

-

Plating

-

Part Decoration

-

Assembly

-

Packaging and more

To learn more about our secondary operations and finishing, please contact EPower Corp for a free consultation.

WHY EPOWER?

Unlike many of our competitors, we have been able to continuously grow because we offer a wide range of turn-key services geared toward quality contract manufacturing, including plastic injection molding. Additionally, to improve the cost advantage and quality of your products, EPower Corp engineers often help customers with new product redesigns including the specification of different materials better suited for the project.

To discuss your project and get invaluable input from an experienced contract manufacturer, please contact EPower Corp for a free consultation.

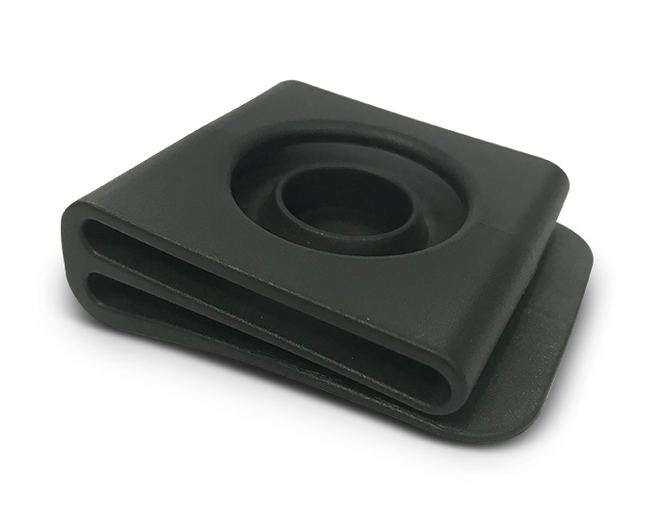

SAMPLE INJECTION MOLDING PRODUCTS

PLASTIC INJECTION TOOLING

With our tools being made in-house, we provide you with quick and safe tooling for your production needs. With these tooling capabilities, we can also offer design for manufacturing (DFM) and a wide range of tool design services. Our engineers are very efficient in designing a tool that will provide our client with the end product they need. When creating new tooling for our clients, we take the following into account:

-

Stress - Knowing how to design your tool to cushion the stress is key for the end product.

-

Gates - The location, type, and design all play a part with the appearance, removal, dimensions, and warping of the part.

-

Wall Thickness - The wall thickness depends on the type of resin that will be used and we know how to design this.

-

Sink Marks - Depending on the thickness, the part will cool at different rates which will cause rejections. We provide solutions to your sink mark issues.

-

Textures - Textures need to be taken into account on the CAD drawings. We know how to design textures on parts that will then be included in the tool.

-

Shrinkage - Shrinkage is a common theme with plastics. Knowing the shrinkage rate for each resin type is key to getting the correct product.

EPower Corp’s Foot Fabrication Capabilities

-

In-House tool design and making

-

4 week standard lead time, depending on the complexity of the tool

-

Guaranteed 500,000 shots per tool. This guarantee per tool may depend on the customer requirements

-

3D and 2D files are accepted

EPower Corp Advantage in Tooling

-

Our engineers have a solid understanding of plastic characteristics, critical when designing a plastic injection tool

-

In-house tooling and production capabilities eliminate the risk of your IP being leaked

-

With tooling and production in one facility, the risk of damaging expensive tooling during transportation is eliminated