Finding a Contract Manufacturer for Your Robotics Product

- Sep 9, 2025

- 4 min read

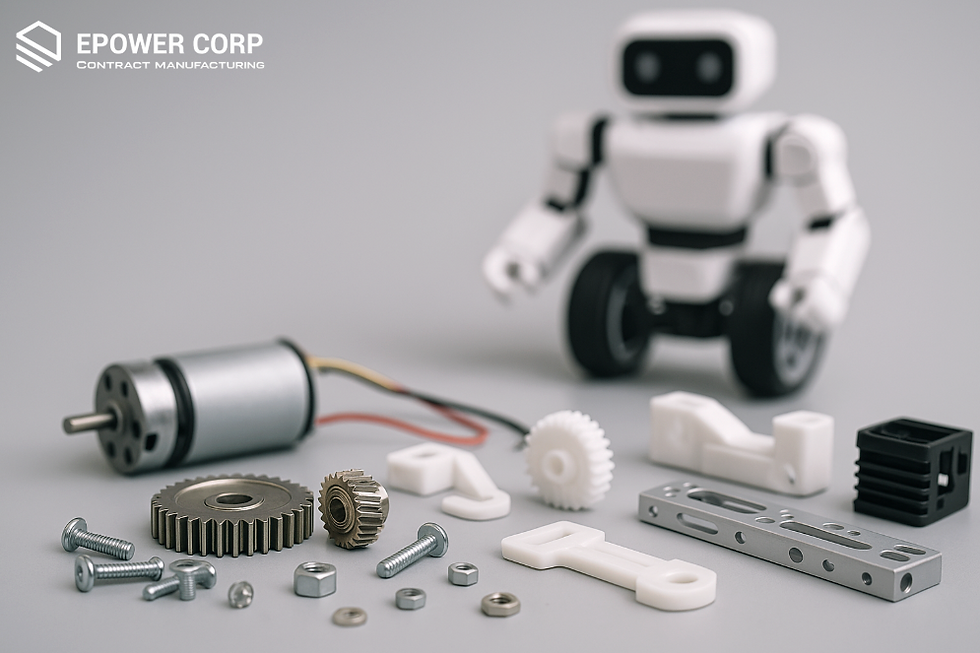

Developing a robotics product is not like building a simple consumer gadget. Robotics products are often electromechanical assemblies that combine mechanical, electrical, and software elements, making the process of finding the right contract manufacturer more complex. A strong contract manufacturing partner can accelerate your path from prototype to mass production, but you need to evaluate capabilities that are particularly critical for robotics.

Below are the key areas to consider when choosing the right contract manufacturer for your robotics product.

Development Capabilities

Robotics products bring together several components and sub-assemblies. It's common for the engineers on these teams to be strong in some areas but not all. For example, you might have a strong software and electronics team, but limited experience in mechanical design and materials. In that case, the right contract manufacturer should be able to fill those gaps by providing mechanical engineering support, design for manufacturing (DFM) input, and guidance on how to transition a design from CAD into a product that can be mass-produced.

Examples of DFM for robotics include:

Adjusting wall thickness and draft angles for injection-molded parts to prevent defects.

Selecting manufacturable tolerances for gears, housings, and linkages so assemblies operate smoothly without unnecessary machining costs.

Designing PCB layouts with production in mind, such as optimizing component spacing for automated assembly and testability.

Consolidating parts to reduce assembly time and potential points of failure.

Beyond DFM, your contract manufacturer should also be prepared to guide you through validation testing, especially with Production Validation Test (PVT). These builds are critical in robotics because they help confirm not just that the product works, but that it works reliably at scale, with real-world stresses applied to motors, sensors, and mechanical systems. A contract manufacturer experienced in these processes ensures you move smoothly into mass production.

Global Footprint

Robotics companies often scale up production gradually, starting with lower volumes before reaching commercial scale. A contract manufacturer with a global footprint reduces the risk of working with a supplier in a single location. While you can't just pick up and move a supply chain, a supplier with global production facilities will be able to work with you if you need to move production out of a certain country for a specific reason.

For example, you may keep your PCB or key sub-assemblies in a country with a mature electronics supply chain (such as China), while moving final assembly to another country to gain favorable tariffs or country-of-origin labeling. Even if you cannot move every part of production, the ability to shift at least assembly and testing can reduce costs, manage geopolitical risk, and improve supply chain resilience.

Assistance with the Certification Process

Unlike simpler consumer products, robotics often requires compliance with safety and performance certifications. These can include CE, FCC, UL, or ISO standards, as well as industry-specific certifications for healthcare, industrial, or defense robotics.

The right contract manufacturer should have experience navigating these processes. They should be able to provide documentation for traceability, support with pre-compliance testing, and coordinate with certification labs. For robotics products, this can also extend to EMC testing, IP ratings (for dust and water protection), and even functional safety evaluations for products that interact closely with people.

In-House Testing and Quality Systems

Robotics products are complex systems; a failure in one sub-assembly (like the motor drive, sensors, or control unit) can compromise the entire product. That’s why robust testing and quality control capabilities are essential.

Seek a contract manufacturer that can provide:

Functional testing for assembled units.

In-Process testing (e.g., testing PCBAs before integration).

Environmental stress testing (temperature, vibration, humidity).

Lifecycle and durability testing for moving parts.

A contract manufacturer with these capabilities reduces the risk of failures in the field and accelerates debugging during development.

Supply Chain and Component Expertise

Robotics products are inherently complex because they require a wide variety of parts. For most robotics brands, managing all of these components directly is not realistic. There are too many suppliers to track the lead time, payment terms, and many other things.

A strong contract manufacturer will simplify this by leveraging their supplier network. Instead of you chasing multiple vendors, you have one company to follow up with on lead times, pricing, and logistics. This not only reduces administrative overhead but also makes your supply chain more predictable.

The right contract manufacturer also adds value by helping you identify alternative suppliers. While you might source off-the-shelf components from platforms like DigiKey or McMaster-Carr, your contract manufacturer can often find local alternatives at a fraction of the price. For high-volume builds, even small per-unit savings on components like bearings, motors, or connectors can add up quickly.

In addition, a contract manufacturer with a strong supply chain expertise will:

Flag long lead-time items early and propose buffer stock or alternative parts.

Help you avoid single-supplier risks by taking on a dual-sourcing strategy.

Leverage their buying power to negotiate better pricing and terms than you could secure independently.

In robotics, where dozens or even hundreds of components must come together seamlessly, this supply chain support can be the difference between a smooth production ramp-up and constant delays.

Conclusion: Finding The Right Contract Manufacturer for Your Robotics Product

Finding the right contract manufacturer for a robotics product requires looking beyond the basics, such as having clear communication, scalability, and other things. Every supplier for all industries should provide this. You need a partner who can support development capabilities, offer a global footprint, guide you through certifications and compliance, provide robust testing systems, and bring strong supply chain expertise to the table. These are the areas that matter most for robotics because of the product’s complexity and the number of disciplines that must converge in one design.

What truly sets a great robotics-focused contract manufacturer apart is their ability to handle the unique challenges of robotics: the intricate supply chain, the demanding validation processes, and the fusion of electronics, mechanics, and software into one reliable product.

By prioritizing these robotics-specific capabilities, you can build a stronger partnership and bring your product from prototype to production with fewer setbacks and greater confidence. If you are looking for a contract manufacturer for your robotics company, then reach out to us. We would be happy to discuss our solutions with you.

Comments