How to Plan Your China +1 Manufacturing Strategy

- Oct 1, 2025

- 5 min read

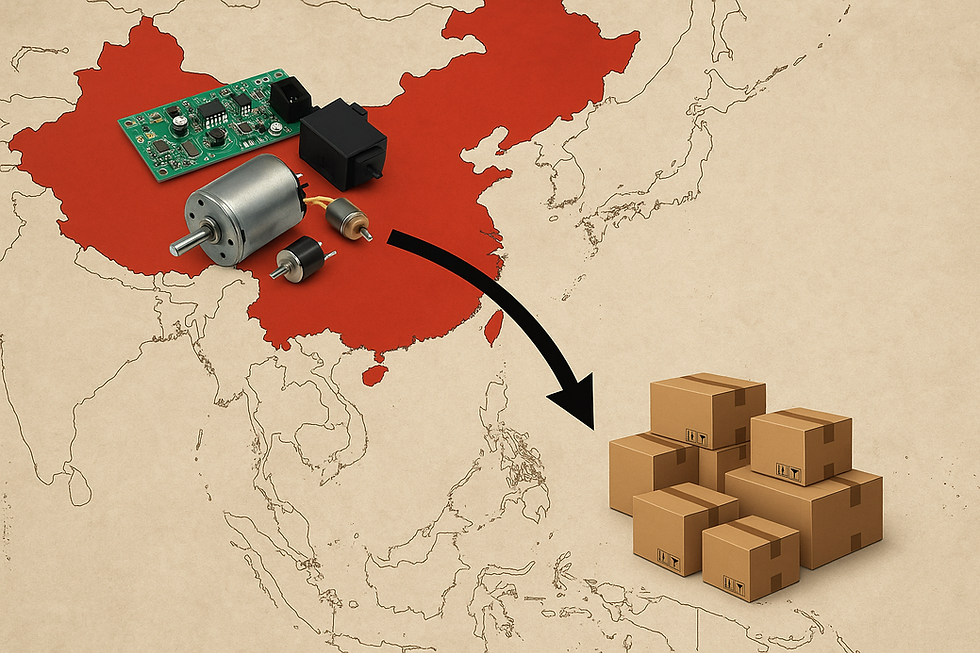

The term China +1 has become a key part of global supply chain discussions in recent years. At its core, the strategy means continuing to leverage China’s strengths in manufacturing while adding a secondary location to reduce risk and create more resilience. Companies are not abandoning China altogether, but rather recognizing that relying on one country alone can leave them vulnerable.

Trade policies, tariffs, rising labor costs, and political uncertainties have shown us that what works right now might not work tomorrow. A sudden policy change or disruption can leave a business without a reliable supplier. By planning a China +1 strategy, you create flexibility in your supply chain. China continues to provide the depth of suppliers and component availability, while your China +1 country, such as Thailand or Vietnam, can handle assembly, testing, or final production. This balance allows you to control costs, manage risks, and keep your product launches on track.

Choosing the Right China +1 Location

Once you decide to diversify your supply chain, the next step is choosing where your “+1” should be. While it’s not reasonable to cut China out of yoru supply chain, the secondary location needs to complement those strengths. For many companies, Thailand has emerged as a leading option.

Thailand offers a strong industrial base, particularly for assembly and final product integration. The government has invested heavily in infrastructure and provides incentives to attract international manufacturers. Its location in Southeast Asia makes it a strategic hub for global shipping routes, allowing companies to reach both Western and Asian markets efficiently.

Another factor is workforce capability. Thailand has developed skilled labor in industries like automotive, electronics, and consumer goods. This makes it easier to set up electromechanical assembly lines without facing the same labor shortages or quality concerns that other emerging markets might present.

Of course, Thailand is not the only option. Countries like Vietnam, Malaysia, and India are also on the radar for many brands. However, Thailand’s mix of infrastructure, government support, free trade agreements, and proven track record in high-quality production makes it especially attractive for companies that want to diversify without compromising on efficiency or quality.

Building Your China +1 Manufacturing Strategy

A successful China +1 strategy isn’t about shifting your entire supply chain out of China. Instead, it’s about finding the right balance between what should stay in China and what can be moved to your secondary location.

China has built a depth of suppliers that is hard to replicate, whether you need custom metal parts, precision plastics, or specialized electronics, the ecosystem is already there. For most companies, it makes sense to continue sourcing components from China, where costs and supplier networks are optimized.

The “+1” country, such as Thailand, then becomes the location for assembly, testing, and final product integration. By moving these later stages out of China, you can reduce tariff exposure, protect against political risks, and improve logistics flexibility. Thailand’s growing role as a manufacturing hub makes it well-suited for this approach, especially for products that combine multiple disciplines like mechanical, electrical, and plastic components.

Coordination between the two sites is critical. A global contract manufacturer that manages both China and Thailand facilities under one roof can streamline communication, reduce risk of misalignment, and ensure consistency across production. This structure allows you to maintain the benefits of China’s supply base while leveraging Thailand’s advantages for final assembly and delivery.

Benefits of a Well-Planned China +1 Approach

When executed correctly, a China +1 strategy delivers advantages that go far beyond simple cost savings. One of the most important benefits is to achieve supply chain resilience. By not relying on a single country, your supply chain can better absorb shocks from tariffs, new regulations, or unexpected disruptions.

Another clear benefit is tariff management. By assembling products in Thailand while still sourcing parts from China, companies can often avoid the added costs tied to U.S.–China trade tensions. This can directly improve your landed costs and help keep pricing competitive.

Lead times also improve when assembly is closer to shipping routes. Thailand’s access to ports and free trade agreements means products can move quickly and reliably to both the U.S. and European markets. For companies developing complex products, this flexibility can make the difference between hitting or missing a launch window.

Finally, a China +1 strategy gives you scalability. If demand grows, you are not locked into one supply chain or one country’s capacity. You have options, and those options give you leverage—not only to grow but also to negotiate better terms with suppliers.

Key Steps to Implementation

Shifting to a China +1 model requires more than choosing a secondary country; it takes careful planning to ensure your supply chain continues to run smoothly. The process often starts with your bill of materials (BOM). Break down your product and identify which components are best sourced from China. In most cases, China remains the most efficient option for custom parts and specialized components.

Next, evaluate which stages of production can be relocated. Assembly, testing, packaging, and quality checks are often the most logical steps to move to your +1 location. These later stages can be managed with less disruption, while still giving you significant advantages in tariffs, logistics, and risk reduction.

Working with a supplier experienced in both China and your +1 country, such as Thailand, makes the transition much easier. A partner who can manage engineering in China while overseeing assembly in Thailand ensures alignment, reduces miscommunication, and helps maintain consistent quality.

Finally, approach the move in phases. Start with a pilot run in your new location to confirm quality and logistics performance before scaling up. A phased transition helps minimize disruptions to your customers and keeps your supply chain steady during the shift.

Conclusion

The China +1 strategy is becoming a necessity for companies that want to protect their supply chains and prepare for long-term growth. By continuing to source components from China while shifting assembly and final production to countries like Thailand, businesses can create a more resilient model that balances cost, flexibility, and reliability.

What works today might not work tomorrow. Tariffs, regulations, and political dynamics can change overnight. A well-planned China +1 approach ensures you’re not caught off guard, giving you the ability to adapt without disrupting production or delaying product launches.

For electromechanical products that depend on multiple components and disciplines, this strategy provides the best of both worlds: the depth of China’s supplier network combined with the advantages of a secondary hub. Companies that make the move now will be better positioned to scale, reduce risks, and stay competitive in global markets.

Comments