Design for Manufacturing (DFM) Tips for Electromechanical Products

- Aug 12, 2025

- 6 min read

Design for Manufacturing (DFM) is one of the most critical steps in bringing an electromechanical product from development to production. When applied correctly, DFM for electromechanical products ensures your design is optimized for production and that you can scale up operations with little difficulty. This process is not just about making a product that works; it’s about creating a design that can be consistently produced, assembled, and scaled without costly rework or delays.

Because electromechanical products use both electrical and mechanical parts that are assembled together, there are a number of challenges that make DFM important. Overlooking a small design detail can lead to assembly difficulties, compliance failures, or unexpected costs when scaling up. By prioritizing DFM for electromechanical products early in development, manufacturers can streamline the transition from prototype to production and set a strong foundation for long-term success.

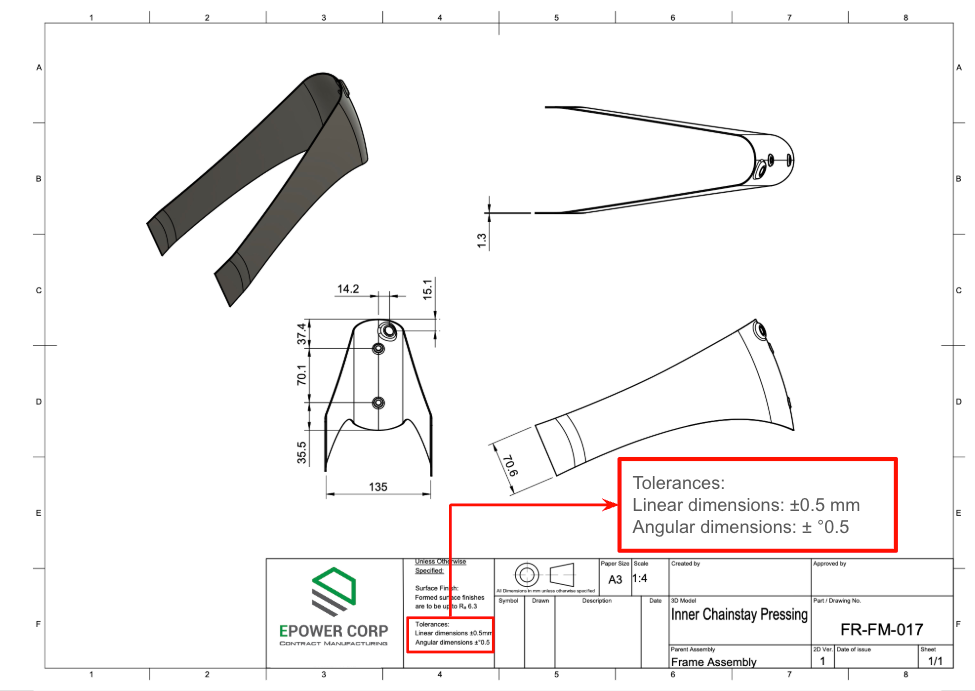

Understand and Manage Tolerances

Tolerances define the acceptable dimensional variation for a part, and in electromechanical products, they are critical to ensuring components fit together and function as intended. However, meeting individual part tolerances doesn’t always guarantee that the final assembly will work. In fact, DFM for electromechanical products often reveals that parts can be “in spec” yet still impossible to assemble.

Imagine a shaft designed to fit into a bearing. The shaft’s diameter tolerance might be 10.00 ± 0.05 mm, while the bearing’s inner diameter tolerance might be 10.10 ± 0.05 mm. On paper, both parts are within their specified tolerances. But here’s where problems occur:

Worst-case high/low fit: If the shaft is manufactured at the high end of its tolerance (10.05 mm) and the bearing comes in at the low end of its tolerance (10.05 mm), they will be exactly the same size and will not be able to be assembled without potential damage.

Assembly rework: Even though both parts technically passed inspection, the fit issue could lead to assembly delays, part rejection, or last-minute modifications on the production line.

The solution is to analyze tolerance stack-ups early in the design stage. Instead of only considering each part individually, look at the combined effect of tolerances in real-world scenarios. This might mean adjusting dimensions, increasing clearance, or tightening tolerances for critical mating parts while loosening them where performance is less sensitive.

In DFM for electromechanical products, tolerance analysis isn’t just about preventing failures; it’s about creating a strong design that assembles smoothly every time, regardless of where individual parts land within their acceptable manufacturing limits.

Choose Standard Components Whenever Possible

One of the easiest ways to reduce complexity, cost, and lead time in DFM for electromechanical products is to use standard, off-the-shelf components whenever possible. Standard components are readily available, have established quality records, and often eliminate the need for costly custom tooling or specialized manufacturing processes.

For example, consider a consumer appliance that requires a fastening system. You could design a custom screw with a unique head shape and thread pitch to meet specific aesthetic and performance goals. However, this would require a custom mold for screw manufacturing, higher minimum order quantities, and potentially long lead times. In contrast, selecting a standard metric pan-head screw that’s already mass-produced allows you to purchase in smaller quantities, avoid tooling costs, and source from multiple suppliers to maintain flexibility.

Here are some other benefits other than just cost savings:

Faster procurement: Common components are often in stock and ready to ship.

Proven performance: Standard parts have been tested and validated in countless applications.

Design agility: If production needs to be scaled quickly, sourcing standard parts from multiple vendors is far easier than finding capacity for a custom item.

In DFM for electromechanical products, standard components can also simplify regulatory compliance since these parts may already meet relevant certifications such as UL, CE, or RoHS. While customization is sometimes unavoidable for unique performance requirements, every non-critical part should be evaluated for a standard equivalent to streamline production and reduce risk.

Confirm Material and Process Compatibility

Material selection is one of the most important aspects of DFM for electromechanical products, but it’s not enough to choose materials solely based on strength, weight, or cost. You also need to ensure that the materials and any planned secondary processes, such as surface finishing, coating, or heat treatment, are fully compatible.

For example, anodizing is a common finishing process for aluminum. However, attempting to anodize steel is far more complicated. While it can technically be done, it requires additional chemical steps, is less durable, and can result in uneven finishes. If a design calls for both aluminum and steel components with a uniform anodized look, this mismatch could create production delays, increased scrap rates, or inconsistent aesthetics.

Other compatibility pitfalls include:

Coating materials that can’t withstand the heat of any secondary process.

Plastic parts that warp during real world use.

Dissimilar metals that may corrode when in contact, especially in humid environments.

In DFM for electromechanical products, confirming compatibility early avoids costly re-engineering later. This means verifying that each material can withstand the required manufacturing processes and that the finished parts will meet performance and durability standards once assembled.

Verify Regulatory and Safety Compliance Early

Regulatory compliance is not something to leave until the final stages of product development. For DFM for electromechanical products, confirming compliance requirements early in the design phase ensures that you avoid costly redesigns, missed certifications, and delayed product launches.

Compliance standards such as UL, CE, FCC, and RoHS can dictate everything from the materials you choose to the way components are insulated or labeled. For example, a plastic housing for an electronic device may need to meet a specific UL flammability rating (like UL94 V-0) to pass safety tests. If the housing is designed with a plastic that doesn’t meet this rating, the product could fail certification, requiring a redesign and retooling.

Another example involves electrical safety. Certain power cords, connectors, or internal wiring must be certified for the target market. If you choose a cost-effective but uncertified component early in development, it may have to be replaced later, leading to changes in tooling, wiring layout, and even enclosure size.

The most efficient approach in DFM for electromechanical products is to identify all applicable compliance requirements during the initial design review. This ensures that every material, component, and process step supports both performance and certification needs, keeping your path to production clear and predictable.

Plan for Assembly Efficiency

In DFM for electromechanical products, designing for easy assembly is just as important as making individual parts manufacturable. Even well-made components can create bottlenecks if they require complicated assembly steps, precise alignment, or excessive handling time. Small improvements to assembly efficiency can significantly reduce labor costs, increase throughput, and improve product quality.

For example, consider a small motor assembly that requires attaching a gearbox to a housing with four screws. If the screw holes are not chamfered, workers may spend extra seconds aligning the screws, time that adds up over thousands of units. Similarly, if a cable needs to be routed through a tight, enclosed space before being connected, assembly time may double, and the risk of damaging the cable increases.

Some common DFM strategies to improve assembly efficiency include:

Designing parts so they can only be installed in the correct orientation.

Grouping fasteners into as few sizes as possible to reduce tool changes.

Allowing easy access to critical connection points for both assembly and maintenance.

When done correctly, DFM for electromechanical products makes assembly faster, more reliable, and less prone to human error, allowing your production team to focus on quality rather than troubleshooting fit and alignment issues.

Build for Scalability from Day One

While initial production runs are often small, the ultimate goal in DFM for electromechanical products is to create a design that can scale efficiently. Designing only for low-volume production can cause major challenges when demand grows, leading to redesigns, retooling, and process changes that could have been avoided with early planning.

For example, an enclosure designed for manual assembly might work well for the first 1,000 units but become inefficient at 50,000 units. A simple feature change, like adding locator pins for automated assembly, could make the product compatible with high-speed equipment without affecting its appearance or performance.

Scalability considerations in DFM for electromechanical products include:

Selecting components that are widely available from multiple suppliers.

Designing parts to be compatible with both manual and automated assembly methods.

Planning for jigs, fixtures, and test equipment that can be scaled or duplicated for higher output.

By thinking about high-volume production early, you not only protect your investment in tooling and design but also ensure that scaling up doesn’t require starting over.

Conclusion: DFM Tips for Electromechanical Products

Effective DFM for electromechanical products is about much more than making parts to print; it’s about ensuring that every design decision supports manufacturability, assembly efficiency, regulatory compliance, and scalability. From managing tolerances to selecting standard components, confirming material compatibility, and planning for future production growth, every step taken in the design stage can pay dividends once you hit the factory floor.

By prioritizing these principles early, you set your product up for a smoother transition from prototype to production and reduce the risk of costly surprises along the way. Partnering with an experienced contract manufacturer can help you navigate these challenges and ensure that your design is ready not just for the first build, but for every build that follows.

Comments