How Tariffs Impact New Product Development

- Aug 13, 2025

- 4 min read

Tariffs have become a significant factor in shaping global supply chains. For companies focused on launching new products, tariffs can influence everything from budgeting to timelines. Ultimately, when there are tariffs, the company will usually have lower profits which can mean less resources that are set aside to new product development. This creates a challenge: how can brands maintain the pace of new product development when the cost of developing each new product increases?

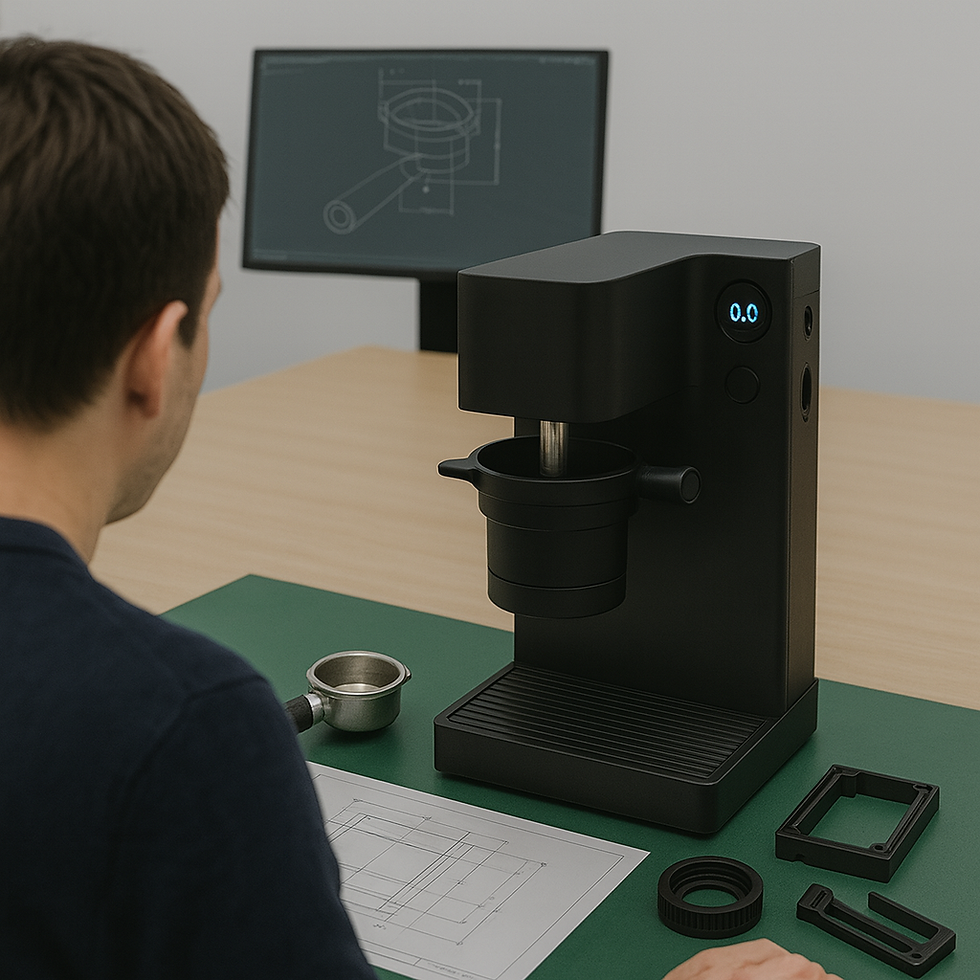

The connection between tariffs and new product development is often overlooked. Rising costs don’t just affect production and your landed cost but they can slow the process of bringing a new product to market. Prototyping, for example, is an essential step in refining a design, yet if these early builds are produced in countries like China, they may also be subject to tariffs. As a result, companies face higher expenses before a product ever reaches production, potentially delaying launches and limiting improvements.

How Tariffs Affect New Product Development Budgets

When tariffs increase the landed cost of materials, components, or finished goods, the immediate impact is on a company’s profitability. Lower profit margins mean less capital available for certain departments, one of those being engineering or R&D. This can result in fewer resources for concept exploration, design engineering, prototyping, and validation testing.

For example, a consumer electronics brand might plan to release three new products in a year, each requiring multiple rounds of engineering and validation builds. But when tariffs drive up the cost of imported components and parts, the total budget for new product development shrinks. The company might then decide to scale back to only two launches, reduce the number of design iterations, or skip certain validation stages.

In short, tariffs don’t just add a line item to manufacturing costs; they can indirectly slow innovation by limiting the funding and flexibility needed to develop new products efficiently.

The Impact on Prototyping Costs

Prototyping is one of the drivers of costs and lead time for new product development and tariffs can make it significantly more expensive. Many companies rely on overseas suppliers, particularly in China, for prototypes because of their speed, manufacturing expertise, and competitive pricing. However, when these prototypes are shipped to the US, they will be hit with tariffs.

This cost might not seem like a lot but when you are constantly making prototypes, then these small amounts add up. For instance, if a company is developing a consumer appliance and needs multiple prototype iterations to refine the design, tariffs on each shipment can make the process far more expensive than anticipated. As a result, teams may feel pressure to reduce the number of prototypes, move forward with less testing, or consolidate design changes into fewer builds. All of which can increase the risk of issues appearing later in the development cycle.

Some companies respond by shifting early-stage prototyping to US based companies but there are still tariffs on all imported raw material. Ultimately, tariffs force development teams to make trade-offs that really should not be made.

Delays in Time-to-Market

Tariffs can also create indirect delays in bringing a new product to market. Higher costs often trigger longer internal budget reviews, extended supplier negotiations, and additional cost-reduction exercises before projects can proceed. Each of these steps adds time to the development schedule.

In some cases, product teams may adjust their processes to save money, such as reducing the number of testing phases or consolidating engineering builds. While these changes might lower immediate expenses, they can increase the risk of quality issues, which could require redesigns or recalls, delays that are far more costly in the long run.

For example, a company developing a new consumer electronics device might opt to combine design validation testing (DVT) and production validation testing (PVT) into a single build to cut prototype costs. While this decision saves money upfront, it reduces the opportunity to catch and fix problems early, which can push back the product launch and make the total development timeline longer.

The result is a slower overall time-to-market, which can weaken a brand’s competitive edge and allow competitors to capture market share.

Strategic Approaches to Keep Innovation Moving

While tariffs can create financial and operational burdens, companies can still maintain momentum in new product development by taking proactive steps to adapt their supply chain and development process.

Diversify the Supply Chain

Producing in countries with lower or no tariffs for your target market can reduce costs and protect profit margins. This might involve a China + 1 strategy, where certain phases, such as final assembly or packaging, are moved to alternative locations like Thailand, Vietnam, or Mexico.

Apply Tariff Engineering

By modifying product design, selecting different materials, or adjusting where final assembly occurs, companies may qualify for different HS codes or rules of origin that carry lower or no tariffs. This can preserve the budget without compromising quality.

Partner with an Experienced Contract Manufacturer

Manufacturers who operate in multiple countries and understand tariff structures can advise on where to source components, build prototypes, and complete assembly to minimize costs. This is especially valuable for complex products requiring multiple suppliers.

Use Hybrid Prototyping Strategies

Companies can combine local, rapid prototyping for early design validation with overseas builds for final pre-production testing. This approach reduces tariff costs while maintaining quality and accuracy in later builds.

By integrating these strategies, companies can continue to innovate and deliver new products without being slowed down by tariff-related cost pressures.

Conclusion: Tariffs and New Product Development

Tariffs and new product development are closely linked, and the effects go far beyond increased unit costs. Higher expenses for materials, components, and prototypes can limit budgets, slow design iterations, and delay launches. While these challenges can dampen innovation, they don’t have to stop it altogether.

By proactively managing supply chains, exploring tariff engineering opportunities, and partnering with contract manufacturers who operate across multiple regions, companies can protect their ability to bring new products to market efficiently. The key is to plan ahead, factoring tariff implications into both budgeting and scheduling, so that cost pressures don’t derail development.

In a competitive market, the brands that can adapt their product development process in the face of tariffs will be the ones that maintain speed, quality, and customer loyalty.

Comments